Technical calculations and simulations are also known under the term CAE, which stands for Computer Aided Engineering. This means that we can later test and calculate real loads on the computer beforehand using models. Long before it is possible to create a physical prototype, calculations and simulations are already carried out on virtual prototypes. This is done first with a 3-D representation of the component, which then interacts with the theoretical models of the respective physical processes.

The calculation thus describes the approximate solution of a real problem via mathematical systems of equations. Simulation in this context means that these models are often calculated several times with different boundary conditions and input variables. Nowadays, this is sometimes even done automatically. In this way, the developers can determine optimal load areas or damage areas of the component under the acting forces.

Why do you use these two terms ?

The aim of technical product development is always to develop the most suitable component for the respective requirement. However, the real production of, among other things, highly complex parts is very cost-intensive. Real experiments can even exceed these costs. That is why every development department now benefits from the ever-increasing computing capacities.

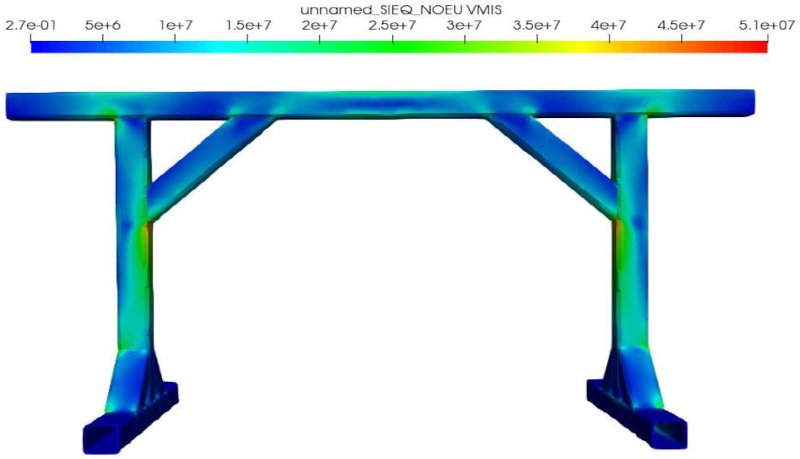

The calculation engineer creates 3D calculation models of the components and simulates the load cases and the resulting mechanical behavior directly on the computer using the appropriate software. Necessary corrections to the geometry or the choice of materials can therefore also be made on the PC in this conceptual and thus more favorable early phase. In this way, both the manufacture of the component and the performance of experiments are initially only simulated. Once it has been fully developed there and all possible doubts have been cleared up, the real production of the prototype is usually started with a clear conscience.

What are the examples of calculations and simulations ?

Examples for simulations are flow processes. If a component is later exposed to a flow in the application, be it by air, gas or a liquid, the model is introduced into this physical model. The flow behavior of the respective medium is modeled according to the respective applicable laws of nature and the later expected real occurring flow and all possible resulting problems are checked. One can think here, for example, of the wings of an aircraft, the car body or individual engine components that come into contact with oil during operation. Other applications include strength calculations using the finite element method FEM or multi-body simulations, so-called MKS.

On these pages you will also learn, how you can accelerate and optimize your product development process with the help of calculations and simulations.

Are you curious ?

Inform yourself about our complete range of services and contact us !