The representation of flow conditions in and around components within the scope of a CFD analysis is an attractive alternative to complex wind or water tunnel tests. The numerical flow simulation enables the fast and cost-effective verification of function and quality of your products. Particularly for components through which flow occurs, it offers the possibility of representing flow in areas where measurement is often hardly possible.

By means of CFD calculations we are not only able to represent flow velocities and pressure losses, but also to depict temperature distributions in the flow space, which can be caused by various heat sources. Mixing ratios, stirring processes or the flow of porous media can also be visualized with the help of CFD simulation. Thus, dead zones and turbulences in the flow can already be detected in the design phase.

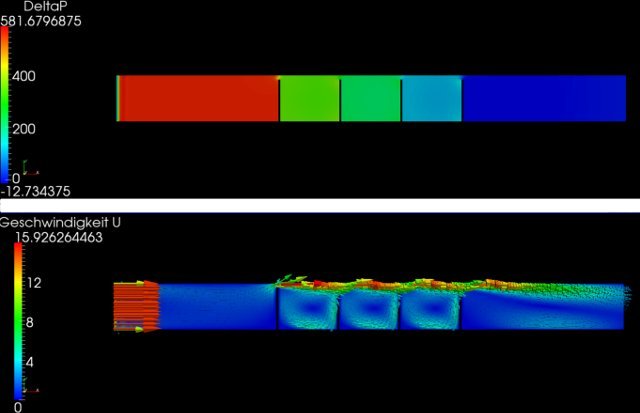

CFD simulation of a labyrinth gap seal

Furthermore, undesirable pressure losses can be avoided by design improvements. This makes it possible to test only those prototypes that have already delivered promising results in the simulation. Avoid component failure and play it safe with our support !

Inform yourself about our services in the field of Computational Fluid Dynamics !

State of the art flow simulation using CFD calculation

Even with modern hardware, turbulent flows can only be represented approximately. The accuracy of the CFD simulation depends on the turbulence model, which has to be selected according to the respective requirements of the flow simulation. For this purpose, a profound knowledge and a certain experience of the calculation engineer is required. A complex CFD analysis, depending on the size of the model and the application, easily leads to immense calculation times. However, our experienced specialists always select the parameters for the CFD calculation that are appropriate to the needs of our customers. Only in this way can the desired flow effects be represented. Furthermore, by coupling the CFD calculation with a FE- Analysis within the framework of an FSI simulation (fluid-structure interaction), to map interactions between flow and structural mechanics.

Procedure for securing the function of your products by CFD simulation

To ensure the optimal functioning of your products, we take a close look at the flow volume limited by the respective components.

Depending on the requirements and specifications for the flow conditions to be investigated within the scope of the CFD analysis, we reproduce reality in the best possible way by selecting the appropriate flow model using appropriate approximations. On request, we contact testing institutes and facilities to determine the respective requirements of the tests or inspections to be carried out and to design your product accordingly. These parameters are used as boundary conditions for the CFD calculation in the form of velocities, mass flows and/or temperatures.

Determination of the substance data for CFD analysis

The accuracy and quality of the results of the flow simulation usually depend on the density, viscosity and also the heat capacity of the fluid used in the temperature range valid for the simulation. We usually take the required material data for all common fluids from the relevant technical literature, unless the data is provided by our customers.

Failure criteria for the evaluation of the CFD simulation

Customer-side criteria are usually specified for the failure assessment of the flow conditions. Corresponding criteria are, for example, pressure loss, mixing ratios and substance concentrations in multi-phase flow, upper temperature limits or particle distributions in certain areas of the flow space (e.g. deposits at the bottom of a tank).

Validation of the flow simulation

Through cooperation with renowned institutes, we are happy to coordinate the following tests or measurements on request:

- Measurements in wind or water tunnel

- Optical measurements for the characterization of flow velocities and particle distributions

- Pressure loss measurements

Validation of a CFD analysis in the wind tunnel

Project examples for numerical flow simulations: