In the FEM simulation of drop tests, the explicit finite element method is used to calculate the component loads. This method, also known as explicit finite element analysis, is used to solve various physical problems, such as the deformation or strength calculation in this case. This partially automated process allows us to calculate all structures and components under the influence of dynamic loads.

In general, this type of FEM calculation allows us to calculate the mechanical response of certain products to real conditions (such as temperature, vibration, force or other physical influences). However, in this particular case, it is used to check the product stability in case of fall. If the product does not fail in actual use, it should also function as expected in the simulation.

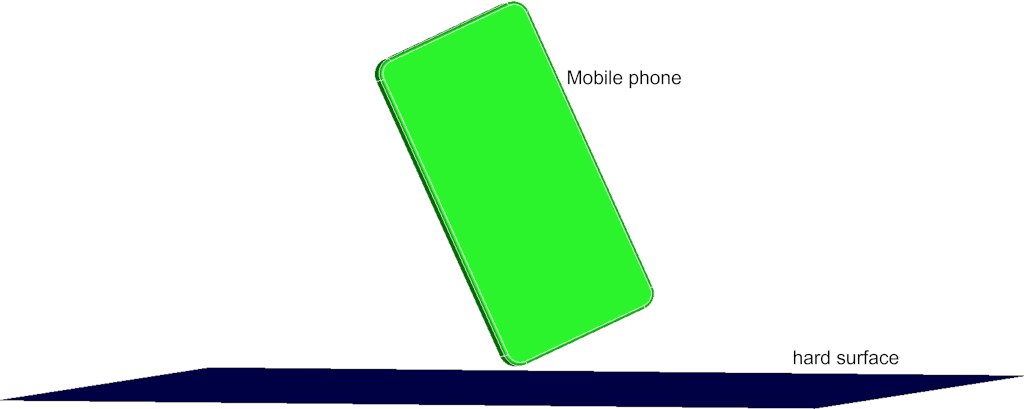

Exactly this can be proven by means of an explicit FEM simulation in the context of a virtual drop test. For this purpose, the objects to be tested are placed at a distance just before contact with the hard surface (impact on the ground). The calculation engineer then applies an appropriate boundary condition (e.g. an impact velocity) to the components to be tested.

Why do we use the explicit FE- calculation for drop tests ?

In order to prove that products are sufficiently resistant to impact loading, either an FEM simulation or a drop test is carried out.

The advantage of simulation is that the strength can be verified without having to destroy the prototype. The impact resistance is therefore usually verified by an explicit FEM calculation within the scope of a virtual drop test.

FE- simulations of drop tests are not only highly dynamic due to their time-dependent loads (velocities, accelerations, etc.), but also often non-linear due to the material behaviour (for example in the case of plastics).

Application examples for explicit finite element simulations

Other common applications for explicit finite element simulations in this context are, for example, crash simulations, snap connections of plastic parts or forming processes. In general, loads with (time-dependent) plastic deformations are often the subject of investigations. Within the framework of the simulation, we can also determine and analyze stiffness losses in the case of structural failure or due to non-linear contact problems.

FEM simulation is frequently used in the automotive industry, especially for short-term dynamics tasks. When it comes to the impact safety of vehicles, these simulations have become an indispensable part of the development process. The investigation of the behaviour of a vehicle's occupants or the impact of a collision on persons involved in an accident is also particularly relevant for automobile and commercial vehicle manufacturers in this context.

For example, special attention is paid to the behavior of a pedestrian during an impact on an engine hood as part of the FE simulation of a drop test. The evaluation of safety-relevant components such as fascia panels, steering wheel or instrument panels is also often the focus of the application for pedestrian and passenger protection.

Through an explicit finite element simulation, we can simulate impact processes for various products from different industries. From protective caps to mobile phones and containers, FE- calculations are frequently used in drop tests. Time and cost reduction are the main advantages that motivate us to test prototypes virtually without building and destroying them. The virtual drop tests bring good results with a manageable effort, which achieve a very good agreement with the real test. However, these are not the only advantages for our customers in the use of FE- simulation for their product development process.

Advantages for our customers

Through the FE- Simulation of a drop test, we can quickly detect damage even inside a device, furthermore, a quick and easy evaluation of different variants is possible. The early detection of various weak points leads to enormous cost and time savings. Above all, the drop test simulation provides information about the drop and impact loads, as well as about stresses and plastic strains in the material.

Drop tests play a not insignificant role in the product development of many different devices and everyday objects. These include, for example, tanks/tank containers, containers, hazardous goods containers, IBC containers and transport containers. But also mobile phones, mobile devices, telephone devices as well as suitcases and storage boxes are among the most frequently tested products. Furthermore, the drop test simulation includes insulin pens, blood glucose meters and also garden tools, home tools and hand drills. For the protection of car occupants, head impact calculations are carried out with the aid of the FE- Simulation.

Are you curious ?

Learn more about the crash simulation or impact simulation, and how you can prove the strength of your components in relation to the occurring loads with the help of a FEM simulation.

Inform yourself about our complete range of services and contact us !