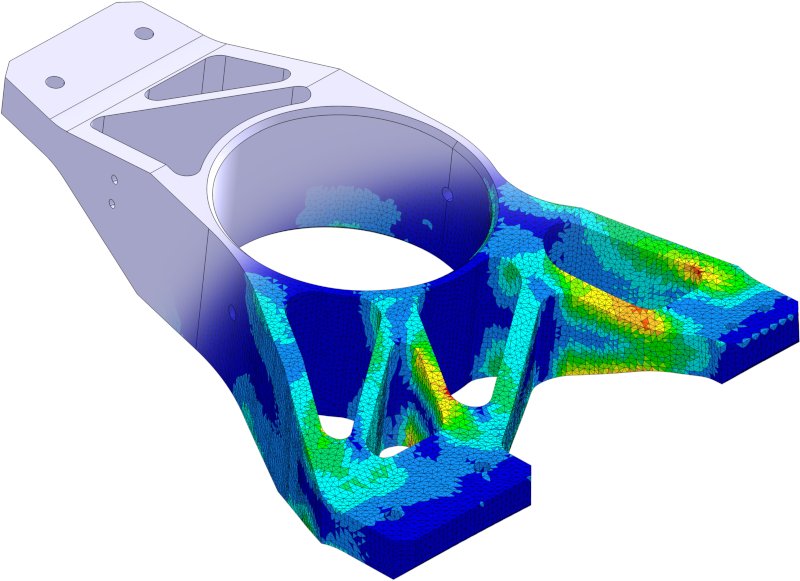

The internal structure of a technical component describes all its elements and their respective interactions. Structural optimization is therefore essential for component optimization and comprises the following three hierarchically arranged stages: topology optimization, shape optimization and cross-section optimization. The industry standard for performing these calculations is the Finite Element Method (FEM).

Topology optimization

The topology of a component is also referred to as its basic shape. This describes its structure, which does not change even under different types of deformation. Basically, this refers to characteristic holes and cavities in an element, but not to their dimensions and characteristics. A ring and a cup with a handle thus have the same shape. Regardless of the details and dimensions and especially after a deformation such as bending or stretching.

Computer-aided optimization of the topology or shape plays an important role in component development. It is mostly used at the beginning of the design process to obtain ideas for a sensible shape. An intelligent choice of shape can save material and, consequently, component weight and material costs later on. All information about the maximum geometric space that the element may occupy later in operation, about the restraints and the loads is fed in. With the help of numerous simulation runs, these input variables are used to determine the optimum design for the component that best withstands the forces acting on it. These then serve as the starting point for the further design steps. The optimization of the topology represents the most flexible optimization stage.

Shape optimization

This type of optimization of the structure of a component, known as "Shape Optimal Design", is based on an already defined topology. However, the results of the topology optimization often show a heterogeneous stress profile, which is homogenized by the optimization of the shape. The model can now be optimized for a specific property. This is done by changing the surface, by varying mainly geometric quantities. Furthermore, it is possible to increase and also decrease angles and to lengthen or also shorten individual elements. For this type of simulation, the finite element method is also used.

Cross-section optimization

In this approach to component optimization, also referred to as "sizing", the topology and shape are already fixed. The variables to be changed are then only values such as the thickness, the cross-sectional area or the moment of inertia of the individual elements.

Inform yourself about our complete range of services and contact us !