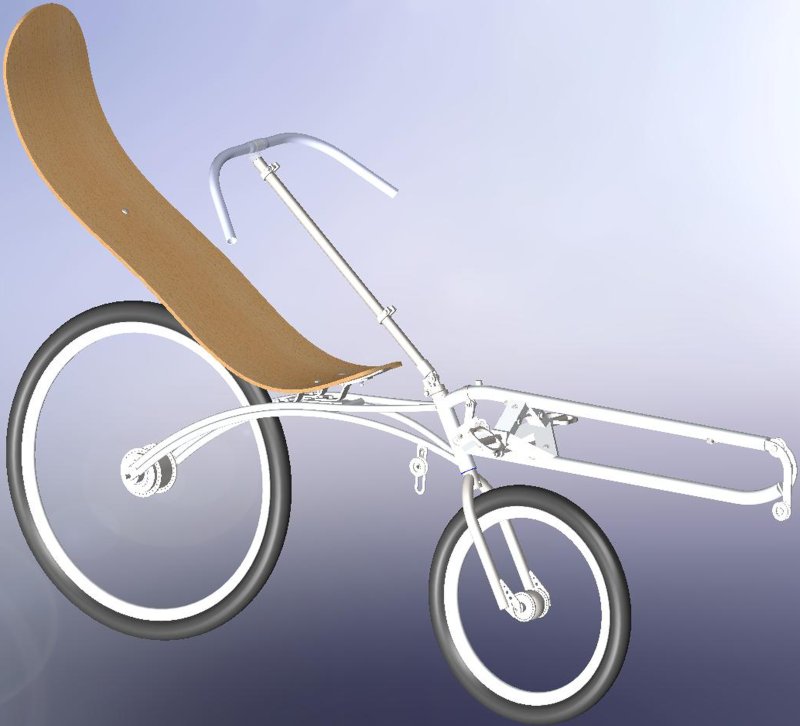

The mechanical construction is in itself something incomplete, because here a completion step by step is necessary. The missing parts are changed continuously after they have been fed into given interfaces and checked. The interfaces can be electronic, optical, fluidic or even mechanical.

Challenges in mechanical design

A mechanical construction is assessed according to the tolerances of the thermal, dynamic and static properties. Subsequently, this results in a homogeneous work of art. The construction must have an economical and safe form. The basis of each construction is a competent knowledge from different economic sectors and companies.

Designing generally means completing the design of a technical product, be it a building, a device, an apparatus, a plant or a machine, in such a way that manufacturing or production is possible. In order to achieve a good work result, technical drawings as well as assembly instructions and other documents are required.

Design fundamentals and pre-development

Before designing can begin, the pre-development process (e.g. on the basis of a Finite element simulation) take place. Here, the function is mostly tested by applying physical laws. The electrical, mechanical or fluidic laws are tested with the help of prototypes, functional samples and simulation models. The organization of a production follows afterwards, whereby the so-called order and work preparation represents an independent process here.

The separation between production-related design and prior development is becoming less and less important in today's world. Both activities are a longer process, which are summarized in the term product development. It ranges from the idea, which stands at the beginning, to the introduction of the product on the market. The documentation of the process contains experiments, results and calculations in the form of functional proofs as well as the documents of the production. In most cases, these are sources of various commercial parts and materials, individual parts and assemblies with tolerance, dimensional, machining and material specifications as well as drawings of the product.

Challenges for mechanical design in modern companies

The core business of a design engineer consists of further and new developments of systems, machines, operating equipment, tools and individual components. Mechanical design generally assumes a key function in a company. In addition, a design engineer controls the prototyping and is significantly involved in the selection of materials. The optimization of elements to save costs for production plays a major role in mechanical design, especially in economically difficult times. Topics such as systematic development and simultaneous engineering are experiencing a renaissance. The ability to view development processes from different perspectives plays an essential role in simultaneous engineering. In addition to the technical perspective, concerns of other units of the organization are also important. For this purpose, sales, purchasing, production and work preparation must be duly considered. This is essential in order to achieve a high level of economic efficiency.

Learn, how we can support you in the development of your products and the creation of mechanical designs !

Are you curious ?

Inform yourself about our complete range of services and contact us !

Thematic contributions

- Equipment design - What you should know !

- Tool design - your tool ready for series production in perfect form !

- Spraying tool construction- What you should absolutely pay attention to !

- Parametric modelling- Faster development through parametric models !

- Plastic design with special material for your highly functional component !